From September 17 to September 21, the 17th graduate mathematical modelling competition of "Huawei Cup 2020" was successfully held under the guidance of the China Academic Degrees and Graduate Education Development Center (CDGDC) of the Ministry of education and sponsored by the Youth Science and Technology Center of the China Association for Science and Technology (CAST).

The national final attracted numerous teams and nearly a thousand students national wide to participate in the competition. Among them, Liu Ziyi, Ni Zhixian, Huang Jingjing, Wei Yan, Ye Jingtian and Fang Ruixue, students of ICARE, participated in the competition with their projects "Construction and application of octane number loss model in gasoline refining process", "UAV cluster cooperative countermeasure (question D)" and "Octane number loss prediction model based on wavelet neural network", which have won the second and third prizes respectively.

Introduction to award winning projects:

Award-winning project: Construction and application of octane number loss model in gasoline refining process

Award: national second prize

Authors: Liu Ziyi (ICARE), Mao Jiaqian and Yi Min

Introduction:

This paper studies the problem of octane number loss in the refining process of gasoline. As the fuel for small vehicles, in order to reduce the impact of the exhaust gas after combustion on the atmospheric environment, gasoline needs to be cleaned in the production process, that is, to reduce the sulfur and olefin content in gasoline, while maintaining its octane number (RON) as far as possible. The finished gasoline is obtained by refining FCC gasoline. This process not only desulfurizes and reduces olefins but also generally reduces the octane number of gasoline, resulting in economic losses. Therefore, it is of great practical significance to optimize the refining unit and keep the octane number as much as possible in-process production.

Award-winning project: UAV cluster cooperative countermeasure (question D)

Award: national third prize

Authors: Ni Zhixian (ICARE), Huang Jingjing (ICARE), Wang Xiaotian

Introduction:

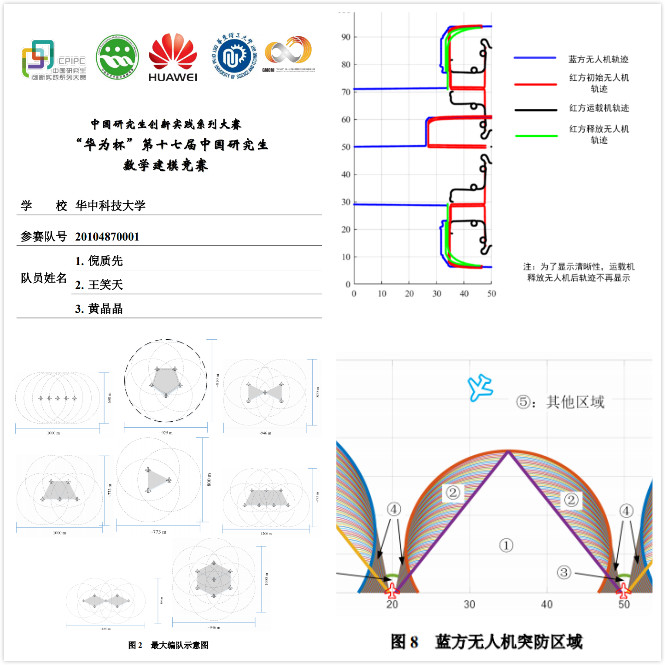

UAV cluster is widely deployed in a modern military war. In this project, series of mathematical lemmas are derived to establish the UAV breakthrough and interception model based on the observation decision framework. On this basis, the project has established a set of global optimal policy and calculated the critical value of penetration bandwidth. Using the strategy function, the corresponding simulation model is further established based on Yalmip to obtain the optimal solution. Then, Nash game theory is introduced to obtain optimal strategies of both sides.

Award-winning project: Prediction model of octane loss based on Wavelet Neural Network

Award: national third prize

Authors: Wei Yan (ICARE), ye Jingtian (ICARE), Fang Ruixue (ICARE)

Introduction:

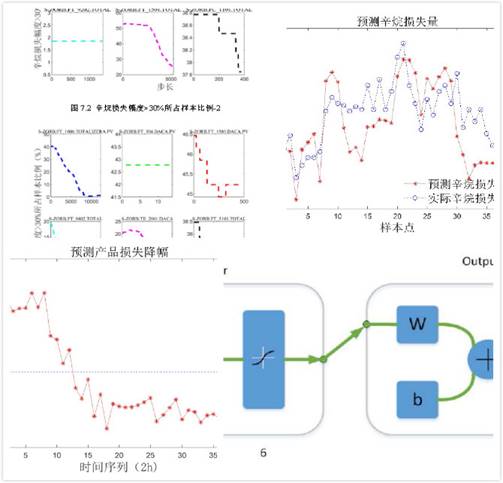

This paper analyzes the historical data of FCC gasoline refining and desulfurization unit in a petrochemical enterprise. Through data mining technology, to find the relationship between processing link and gasoline performance output, which is of great significance to the production of high-performance gasoline. Firstly, the project members process the data of 285 and 313 samples according to the method of sample determination. Then, they transform the original 367 variables into 28 variables by principal component analysis. Then, they demonstrate the rationality of dimension reduction by theory and Durbin Watson test. Considering the nonlinear and coupling relationship between a large number of variables, they use wavelet neural network to establish a prediction model of octane number loss, and the overall prediction error is small. On the premise that the sulfur content is not more than 5 μ g / g, the octane number loss prediction model is used to obtain the optimized operation range set of 22 operation parameters through univariate sample analysis. The sulfur content in the product is fitted by logistic regression. The randomness table of H-L test and H-L test shows that the fitting model is suitable, so as to establish the goal programming, which can be used to evaluate the sulfur content in 133 samples within 2 hours The loss reduction of octane was optimized for No.1 sample. In terms of effect, the average value of octane in 2 hours is 89.01, the octane loss amplitude is 29.6%, and the sulfur content of the product is always less than 5 μ g / g.